Khoom siv

| Lub cev | Aluminium (5052) ● | Hlau | Stainless hlau | |

| Ua kom tiav | Polished | Zinc Plated | Polished | |

| Mandrel | Hlau ● | Stainless hlau | Hlau | Stainless hlau |

| Ua kom tiav | Zinc Plated | Polished | Zinc Plated | Polished |

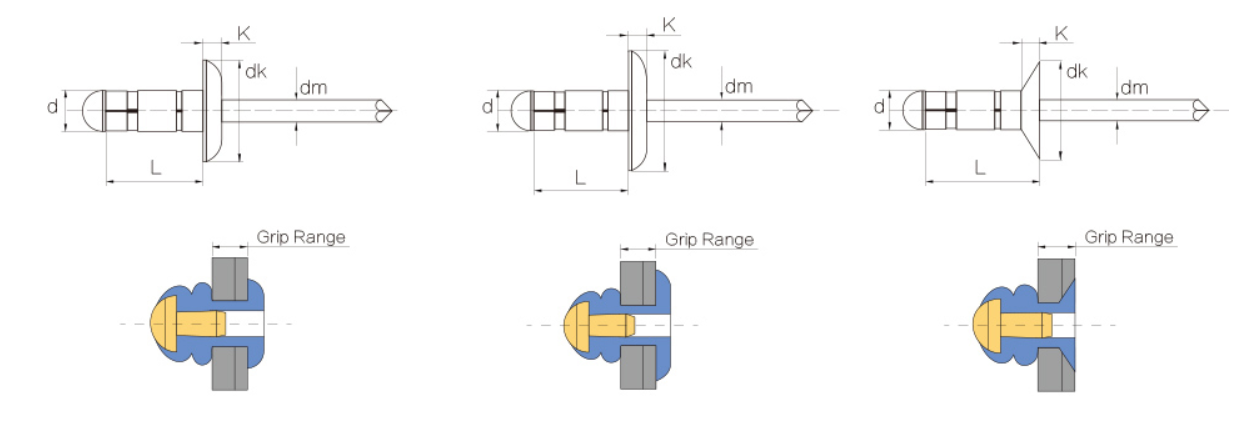

| Hom Lub taub hau | Dome, CSK, Loj Flange | |||

Specification

| D1 NOM. | DRILL NO.&HOLE SIJE | ART.CODE | GRIP RANGE | L (MAX) | D NOM. | K MAX | P MIN. | SHEAR LBS | TENSILE LBS | ||

| INCH | MM | INCH | MM | ||||||||

| 1/8 " 3.2mm ib | #30 3.3-3.4 | SIB 42 | 0.031-0.134 ib | 0.8-3.4 | 0.283 ib | 7.2 | 0.252 " 6.4 | 0.051 " 1.30 Nws | 1.06 " 27 | 135 600 N | 202 900n ua |

| SIB 43 | 0.031-0.187 Nws | 0.8-4.8 | 0.331 ib | 8.4 ib | |||||||

| SIB 44 | 0.046-0.250 Nws | 1.2-6.4 ib | 0.390 ib | 9.9 ib | |||||||

| SIB 45 | 0.156-0.312 ib | 4.0-7.9 | 0.453 ib | 11.5 | |||||||

| SIB 46 | 0.216-0.375 Nws | 5.5-9.5 | 0.516 ib | 13.1 | |||||||

| SIB 47 | .250-0.437 ib | 6.4-11.1 | 0.610 ib | 15.5 ib | |||||||

| 5/32 " 4.0mm ib | #20 4.1-4.2 | SIB 52 | 0.020-0.125 hli | 0.5-3.2 | 0.283 ib | 7.2 | 0.312 " 7.9 ib | 0.063 " 1.60 ib | 1.06 " 27 | 213 950n ua | 337 1500 Nr |

| SIB 54 | 0.046-0.250 Nws | 1.2-6.4 ib | 0.390 ib | 9.9 ib | |||||||

| SIB 55 | 0.125-0.312 ib | 3.2-7.9 | 0.453 ib | 11.5 | |||||||

| TIAB SA 56 | 0.156-0.375 ib | 4.0-9.5 Nws | 0.516 ib | 13.1 | |||||||

| TIAB SA 57 | 0.250-0.437 Nws | 6.4-11.1 | 0.610 ib | 15.5 ib | |||||||

| TIAB SA 58 | 0.250-0.500 Nws | 6.4-12.7 Nws | 0.681 ib | 17.3 ib | |||||||

| 3/16 " 4.8mm ib | #11 4.9-5.0 Nws | TIAB SA 64 | 0.062-0.250 Nws | 1.6-6.4 ib | 0.421 ib | 10.7 ib | 0.386 " 9.8 ib | 0.071 " 1.80 ib | 1.06 " 27 | 296 ib 1 320n | 450 2000 N |

| TIAB SA 65 | 0.079-0.315 Nws | 2.0-8.0 Nws | 0.492 ib | 12.5 ib | |||||||

| SIB 66 | 0.125-0.375 hli | 3.2-9.5 Nws | 0.587 ib | 14.9 Nws | |||||||

| SIB 67 | 0.187-0.437 Ib | 4.8-11.1 Nws | 0.610 ib | 15.5 ib | |||||||

| TIAB SA 68 | 0.250-0.500 Nws | 6.4-12.7 Nws | 0.681 ib | 17.3 ib | |||||||

| TIAB SA 610 | 0.345-0.590 Nws | 9.0-15.0 Nws | 0.783 ib | 19.9 Nws | |||||||

| TIAB SA 612 | 0.500-0.781 Nws | 12.7-19.8 Nws | 0.992 ib | 25.2 ib | |||||||

Daim ntawv thov

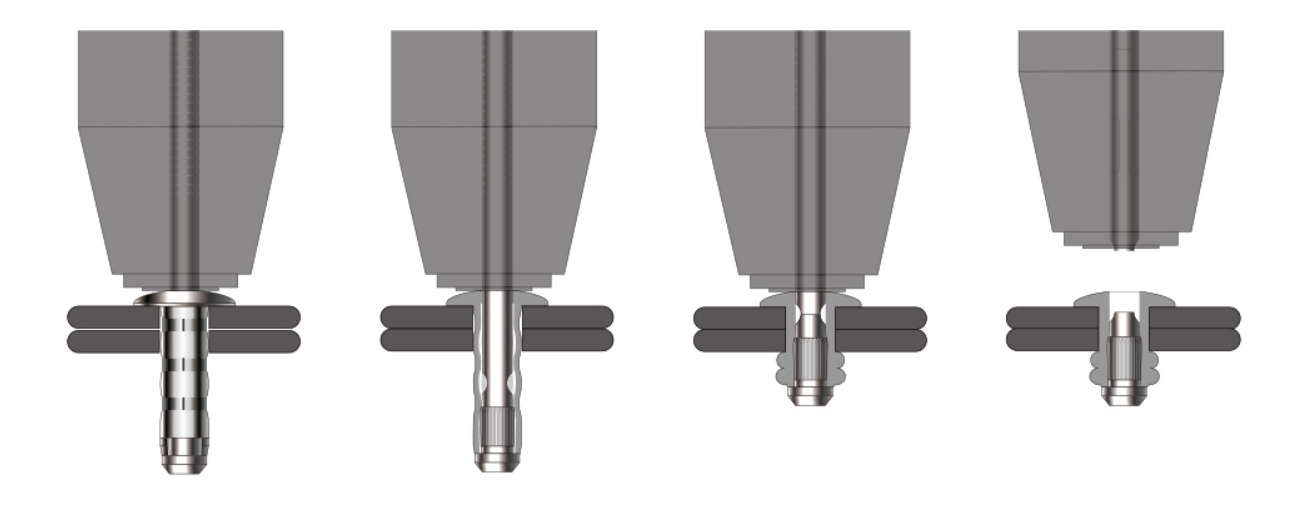

Multi-Grip rivets muaj ntau yam tuav.Thaum lub sij hawm riveting, lub rivet core rub qhov kawg ntawm lub rivet lub cev mus rau hauv ib tug ob lub nruas zoo, clamps ob structural tswv cuab yuav tsum tau riveted nruj nreem, txhim kho sealing rau huab cua tsis kam thiab txo lub siab ntawm cov txheej txheem cov tswv cuab.Multi-grip pop rivets muaj nyob rau hauv cov khoom ntawm txhuas, hlau thiab stainless hlau, thiab muaj kev xaiv ntawm dome taub hau, csk taub hau thiab loj flange taub hau.

Daim ntawv thov: Multi-grip dig muag rivets feem ntau yog siv rau riveting ntau yam txheej txheem nyias hauv ntau lub tsheb, nkoj, kev tsim kho, tshuab, hluav taws xob, thawv, txhuas rooj plaub, khoom siv thiab lwm yam lag luam.

Pop rivet yog ib hom riveting ib feem, uas yog tsim rau riveting ntawm ntau yam ntaub ntawv.Nws muaj lub zog fastening.Nyob rau tib lub sijhawm, cov khoom siv siv tau zoo heev, thiab cov txheej txheem tsim khoom yog qhov siab.Kev ua tau zoo ntawm cov pop rivet ua tau zoo dua qub

Kev kho saum npoo ntawm pop rivets muaj xws li:

1. Electroplating txheej txheem: txheej txheem kev kho saum npoo tuaj yeem siv rau ntau qhov hlau.Electroplating txheej txheem yog siv los ntawm pop rivets, uas tuaj yeem tiv thaiv pop rivets thiab tiv thaiv lawv los ntawm hnav lossis corrosion.

2. Xim txheej txheej: txhim kho qhov zoo nkauj ntawm pop rivets, thiab txheej txheem xim sib txawv raws li qhov xav tau.Cov xim yog ci thiab tsis yooj yim rau ploj, uas tuaj yeem tiv thaiv qhov chaw ntawm pop rivets rau qee yam.

Nrog rau txoj kev loj hlob ntawm kev lag luam niaj hnub, pop rivets tsis yog tsuas yog zoo meej hauv kev ua tau zoo, tab sis kuj zoo heev hauv cov tsos, nrog rau cov nyhuv zoo nkauj, thiab txhawb kev nthuav dav ntawm cov peev txheej ntawm daim ntawv thov ntawm pop rivets.